10 Ways to Optimise dock-to-stock processes for GCC eCommerce success

E-commerce is still said to be in its infancy in the Middle East, compared to other regions in the world, and has begun to grow quite quickly. Couple this with the 142% increase in (specifically UAE) consumer spend over the past four years, and you can see the beginnings of an omnichannel, distribution-centric trend that will carry warehousing companies and manufacturers into a new era.

However, it’s not all coming up roses:

Competition in retail, electronics, real estate, and brick-and-mortar vs online retail is being felt across the region, with costs rising, and international competitors like Amazon and Alibaba coming into the field.

This is why you need to make your warehouse as competitive as possible by reducing your operating costs, optimising your facility use, and increasing your avenues to market for both your business and your supplier brands.

We’re taking a look at each productivity-boosting requirement one by one so that you can make the adjustments to your GCC-based business that will keep you on par with the global players.

Keeping ahead of the curve with dock-to-stock process optimisation:

As pressure mounts to keep up with Amazon and other global players, your warehouse processes will come into sharp focus.

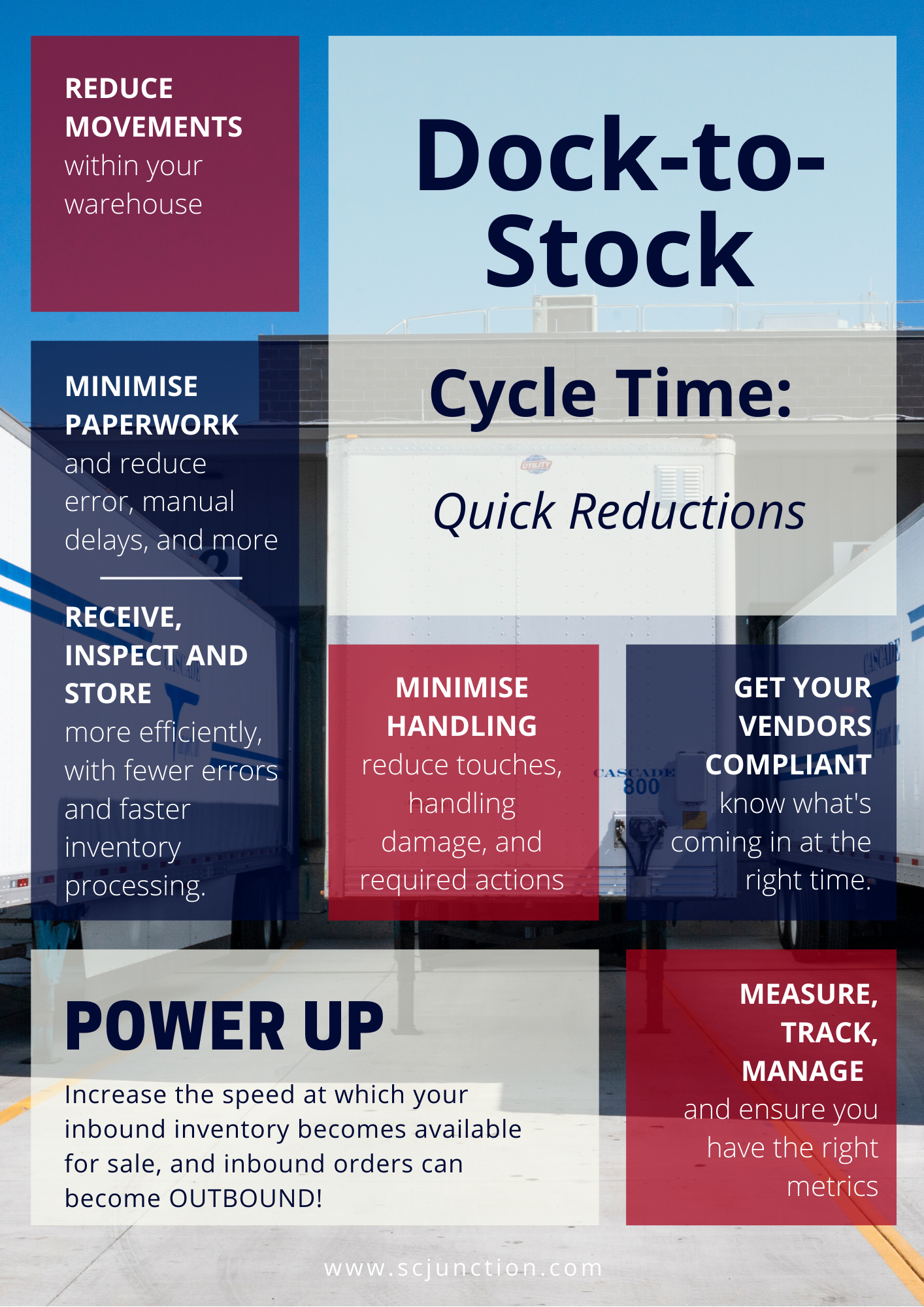

Within your supply chain, there are many impacts which reduce your efficiency, slow your routes, and interrupt stock availability, and these impacts negatively affect your customer satisfaction. This is what you can do to resolve these delays:

.png?width=600&name=Dock%20to%20Stock%20Summary%20(1).png)

Your inventory management methods could be costing you money. Optimising and streamlining the flow of products in and out of your warehouse provides you with a multitude of cost-saving benefits:

- Lower working capital

- Reduction in logistics cost burden

- Savings from decreased obsolescence

- Revenue uplift from fewer permanently lost sales orders

How to achieve these inventory-related productivity improvements:

YOUR AIM: To increase the speed at which your inventory becomes available for sale.

As we discuss in our WMS overview, whether you are receiving against Advanced Shipping Notices (ASNs), PO’s or blind and whether your inventory is labelled, pre-allocated or arrives unplanned, mistakes and errors during the receiving process negatively affect every downstream process that follows in your warehouse.

HOW? Ensure that you are driving an effective receiving and putaway process.

Here are the 10 ways your WMS can streamline your dock-to-stock receiving process, facilitate a smoother inbound and outbound transition, and help you to track, measure, and optimise your methodology for a more efficient workforce and warehouse.

- Get what you need, when you need it, in time for distribution to your customers.

- Follow up on your yard management and appointment scheduling for smoother delivery / receiving processes.

- Optimise your receiving process to ensure that errors can be – and are – reduced, minimising the impact on your inventory control down the line.

- Tighten up on how you receive, what documentation you use, and how you label and log your inventory on arrival.

- Ensure your reverse logistics are fluid and deal directly with your end customers in an efficient and trackable, practical way.

- Sustainably match orders to facilitate cross-docking, including flow-through, merge in transit, ship to mark for, and pure cross-docking.

- Gain ease of tracking and better inventory control with put to store, opportunistic substitution and allocation.

- Use your WMS to ensure your floorplan is arranged in a simple, easy-to-navigate, practical way. Inaccessible stock cannot be sold as simply.

- Don’t let labelling issues get the better of you – Use your WMS to track and label products clearly, to avoid confusion within your inventory.

- An effective putaway process assists in speeding up your order fulfilment time - WMS helps to optimise your putaway strategy, allowing you to improve warehouse capacity, inventory availability, as well as reducing excess travel, preventing damage to inventory and reducing congestion in aisles.

In our next blog, we will be looking at the competitive advantage that you give your business with a picking strategy that improves your pick face, picking pace, and picking accuracy.

Until then, find out more about optimising your warehouse with our Warehouse Optimisation Checklists

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- smart warehouse (4)

- 3PL (3)

- News (3)

- Press Release (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%