COVID-19 Supply Chain Impacts ON THE GCC: What to focus on right now.

.png?width=975&name=COVID-19%20Supply%20Chain%20Impacts_%20What%20to%20focus%20on%20right%20now.%20(1).png)

Over the past few years of digital transformation in the retail sphere, changing customer behaviours, and new demands, our supply chains have not become more robust to handle the additional pressure.

Now, with COVID-19 knocking on our warehouse doors, we have a massive gap to bridge to make it safely to the other side of this crisis.

There are a few reasons that the global supply chain structure - and by the same token the supply chain throughout the GCC in the UAE, Saudi Arabia, and more - has not been reinforced, and most of it comes down to our ability to do basic maintenance on processes, technology, and optimisation.

- Our increasing efficiency and turn-around has given us a lastminute.com approach which works satisfactorily in economic growth periods but fails dismally at the first sign of trouble.

- Rigid regulations, loyalty, and contracts have made it near impossible to bring any kind of flexibility to our supply chains, and so our ability to switch between manufacturers, producers, wholesalers, or importers who can flesh out our inventory when things get tight is… non-existent.

- Probably informing this is our next point: when supply chains are manually managed, it becomes a task of Herculean proportions to ensure that our suppliers are logged, customers are onboarded, inbound orders can be changed and tracked simply, and other process hurdles can be cleared.

- Also contributing is a lack of supply chain transparency – without the correct business intelligence or supply chain intelligence tools to provide a full view of the supply chain’s progress to all levels of management. An unclear path behind you will remain unclear moving forward, and it is almost impossible to manage a disruption of this magnitude without clarity which permits swift, focused proactive measures.

- Specialised industry hubs, considered the best way to reduce costs and localise production for distribution, have become large, immovable blockades on our routes to gaining a free-flowing supply. While we have reduced costs and improved turnaround times, we have also limited our ability to do business when one major production centre goes down.

It seems that our ambitions have led us down this rigid and unwavering path, and now the quest for fast, fantastic, full-service excellence has let us down terribly.

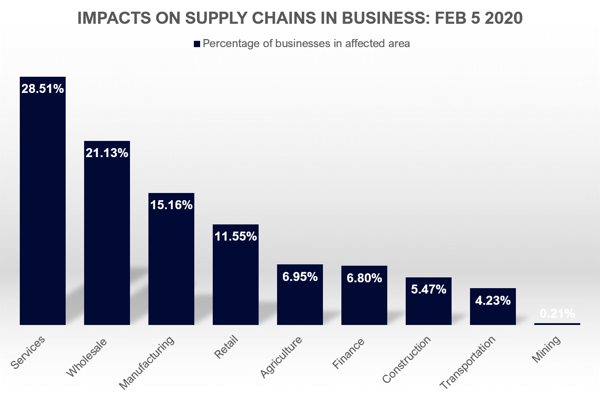

The Supply Chain Industry Verticals Impacted by COVID-19

In a report generated to examine the rise of Coronavirus and its impact on the global supply chain, Dun & Bradstreet discuss the early-stage development and impact of the COVID-19 pandemic. While this was still uniquely a Chinese problem, they had already pinpointed the impacts across global supply chains. Now, we can extend those impacts to almost every country on earth, and more specifically, to our local supply chains throughout the Middle East and GCC region.

SOURCE: Dun & Bradstreet (February 5, 2020)

This means, indeed, that now that Coronavirus has spread across the globe, no business can rest on their prior success and rely on a supply chain operating on outdated rules.

The game has changed.

New processes, new thinking, and new avenues for Warehousing, Distribution and Supply Chains.

It may seem like we have a bleak outlook, but the intention is to make industry players aware of exactly what’s coming – and give you the tools to mitigate the impact that this pandemic may have on your supply chain and bottom line going forward.

Supply Chain Risk Management for the Middle East going forward:

Start using risk-based assessment processes which enable you to reduce your risk regarding suppliers, your suppliers’ suppliers, and alternate options in case of emergency. Build contingency plans, and put in the technological measures in place to support these contingencies.

Ensure your labour management is in line with GCC-, Middle East-, or country-specific risk management best-practices, and that you can safely transition between protocols when the need arises.

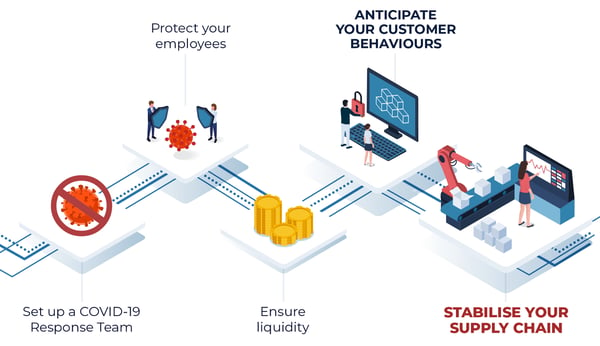

Summary of actions from McKinsey’s Report: COVID-19: Implications for Business

Let’s look at the critical elements from the graphic above that we can help with in the Middle East:

Anticipating customer behaviour during the COVID-19 pandemic:

Based on your existing research, trends, and schedules, you’ll have a handle on your customers’ behaviour in ordinary times. Now, seek out the channels that will help you to connect with your customers as they change their behaviours.

Digital and social channels are available in almost every locale on earth, not least in the GCC region where the channel is growing, so an omnichannel strategy for customer retention will help you to connect, communicate, and convert customers.

A study by Google Trends found that customers who are given the option to switch between the online and physical shopping environments are 30% more likely to remain lifetime customers – and now, they have no choice. In essence, neither do you.

The key omnichannel tools that will help you to access your Middle Eastern markets and consumers are:

-

Available to Commerce

Planning and Managing how you make your entire network inventory available for sale.

-

Clienteling

Personalising the shopping experience for every customer.

-

Distributed Order Management

Orchestrate the flow of orders from any point in your supply chain.

-

Customer Service

A single solution that empowers your service representatives with all of the information they require to delight your customers regardless of how, when or where they purchased from you.

-

POS

A single solution that enables your associates to manage all transactions regardless of which channel they wish to interact with.

-

Store Fulfilment

The ability to receive, pick, ship and manage inventory within your stores so that you can service your customer orders from available store inventory if required.

How to stabilise your supply chain within the GCC:

1. Go digital

We say this often, and we’ll say it again: manual processes in today’s climate without COVID-19 are Kryptonite to your business. Add a global pandemic into the mix, and the impact on your supply chain, distribution centres, and warehouses is magnified.

Without connecting digitally to your buyers or suppliers, there isn’t much chance of building a robust and agile supply chain, as all the players are on different fields.

2. Automate, automate, automate!

Automation on a software level and automation on a hardware level are two completely different beasts, and if you need to start somewhere: automate your processes, and ensure the data you’re tracking is in real-time, giving you a full view of your inventory, labour allocations, inbound orders, shipping processes, and more.

Once you’ve become au fait with the process automation, you can further optimise by implementing unmanned MHE and the like.

3. Get critical with analytics

Start really paying attention to your entire supply chain. Examine your inbound orders, use the tools that your digital platform gives you, and start critically assessing whether each component drives toward or away from agility.

These are the kind things you can assess using a well-implemented WMS:

-

Inbound Logistics

See how your yard management can be improved, your appointments are tracked (and who keeps them or not), how receiving is processed, and where you can improve the strength of these processes based on each delay, delivery, error, and quality check.

-

Inventory Management and Control

Examine the processes through which you manage putaway, stocktake, cycle counting, and lot tracking. Watching inventory in real-time allows you to plan better, schedule better, and accommodate disruptions without blinking.

-

Outbound Order Processing

Smoothing your outbound order process will help you to manage better in times of high-volume and time-sensitive deliveries – like those our panic buying has brought upon us. Wave planning, picking processes, and outbound quality audits ensure a swifter response – and help to ensure that the product is shipped timeously, without knowing over the rest of your processes.

-

Shipping and Loading

How does your shipping process help you to ensure a smooth and seamless service? How does your logistics department add flexibility to your outbound capabilities? And which components of your shipping, routing, and documentation processes need to be reassigned or overhauled?

See more metrics that you can use to ensure your warehouse is performing at an optimum here:

4. Start a conversation

As Supply Chain Digital suggests, we need to open up the discussion to our industry partners , suppliers, and governance bodies within the Middle East and beyond to establish how we revolutionise the supply chain industry throughout the GCC region.

Are consolidated centres of production a good idea? Is there still a need for the same widget to cross the Pacific multiple times before arriving at the end consumer? And does technology create an opportunity to build an alternative, more sustainable global supply structure? - Mikkel Hippe Brun, Supply Chain Digital 14 March

Start a conversation with us: let’s start your business on the right path with a Warehouse Management System which gives you critical tools in the fight against (unexpected) disruptions, and can contribute to your flexible, omnichannel approach.

Until then: Calculate the ROI of your WMS Implementation with our Guide:

TAGS

- WMS (51)

- Warehouse Best Practice (46)

- Implementing a WMS (29)

- Managing your warehouse (19)

- Omni Channel (18)

- eCommerce (18)

- Blog (16)

- Supply Chain Best Practice (16)

- Customer Journey (9)

- Mid-Level (8)

- Warehouse optimisation (7)

- General Tips (5)

- Industry General (5)

- Information (5)

- Trends (5)

- managing your Supply Chain (5)

- saudi arabia (5)

- smart warehouse (4)

- 3PL (3)

- News (3)

- Press Release (3)

- ERP (2)

- Entry-level (2)

- ROI (2)

- Case Study (1)

- OMS (1)

- Picking (1)

- Solution-Specific (1)

- Transport Management System (1)

Take A Look At The Results Of A Successful WMS Implementation.

See how Tarsus Distribution, in collaboration with SCJ boost overall efficiency by 60%